Printing StackaRack STL Files

Our in-house test prints were printed on an Anycubic Mega S, using PLA or PLA+ filament. Results may vary from printer to printer, or with different filaments, so if you find that doing something different works better for your printer, feel free to share!

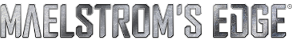

The main unit halves and the base can be printed lying flat on the build plate, with supports set to 'Touching Buildplate' or your printer's equivalent so that it just generates supports to the overhanging areas like the clip insets. For accuracy, we recommend printing these parts at .2mm or better.

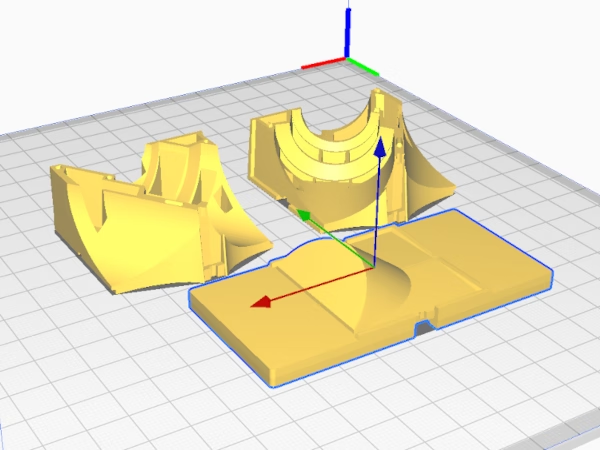

We did find with some filament that the unit halves warped slightly when printed flat as the corners tended to lift off the build plate. For the cleanest and most accurate results all around, printing with these parts at a 30 degree angle, with supports set to 'Touching Buildplate' is best, but does use more support material and adds to the print time.

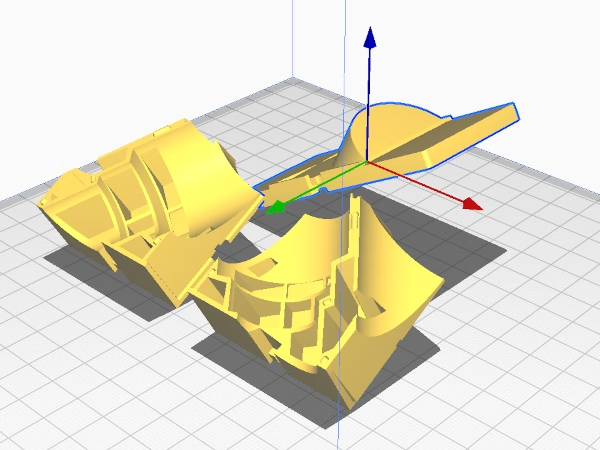

The clips and front panels can be printed lying flat on the buildplate with no support, but because they are small parts that can be dislodged easily, we recommend adding a brim. We would also recommend printing the clips with .1mm or smaller layers for accuracy. Note that these were designed to be a tight fit at injection moulding tolerances, and can't really account for all of the potential differences from printer accuracy or filament, so may need a little scale adjustment to get a good fit on your printed units - If they are too tight, print them with the length of the clip slightly upscaled, or downscale them slightly if they are too loose to hold the units securely. You can, of course, also just skip the clips and glue the units together.

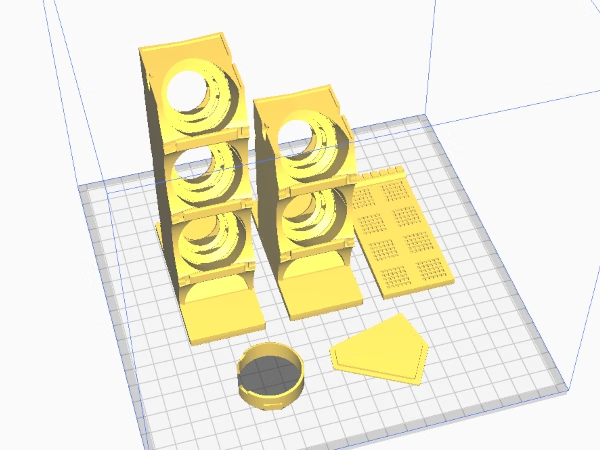

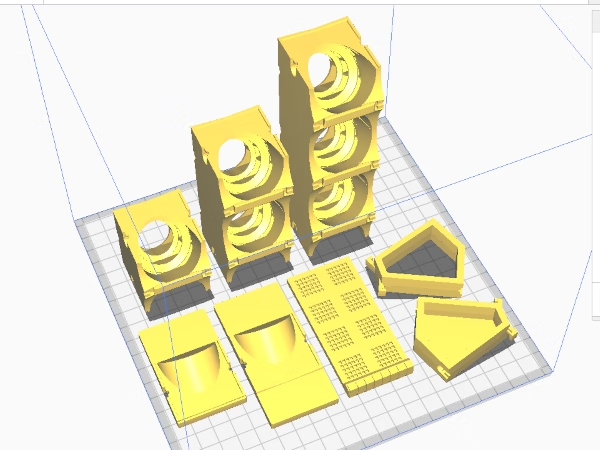

For the parts from the Digital Plus pack: The 2- and 3-stack units with bases, the flat version of the top shelf, the adapter ring and the base piece for the corner can be printed upright with no supports, although the stacks may need a little cleanup around tops of the clip insets. As with the regular components, we recommend printing with .2mm layers or smaller.

The other components can be printed upright with supports set to 'Touching Buildplate', as they need support for the underside of the unit stacks and other overhangs.

With all of this, some cleanup may be required to get parts to fit together snugly, depending on the tolerances of your printer and filament.